Crescere, Innovare Qualificare

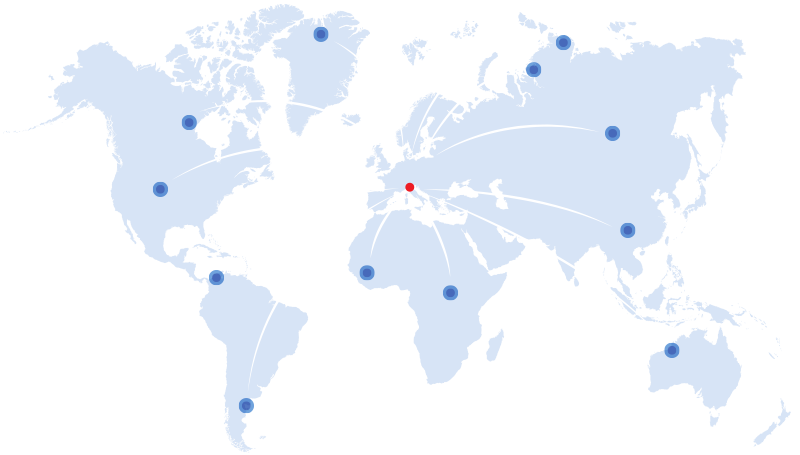

Poliblend by Ascend è ormai una realtà di riferimento per ESPERIENZA e capacità di INNOVAZIONE.

Qualità certificata e ampiezza di gamma

Queste sono le caratteristiche dei prodotti

SOSTENIBILITA'

Un Valore diventato Stile di Vita